Up until now I have always been an air cooler man when it comes to CPU cooling, favouring the Nocuta NH-D14 using a three fan configuration. However, even the mighty NH-D14 is not man enough to tame an Intel Core i7-3930K Hexa-Core Processor fully overclocked! Also, most of the performance memory is now so tall (as you will see later), that it just will not fit under the fans of a CPU air cooler.

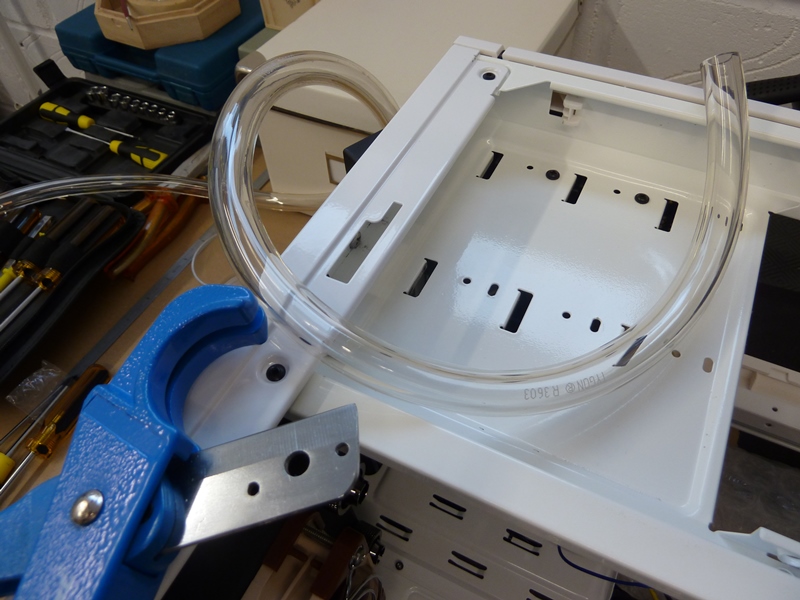

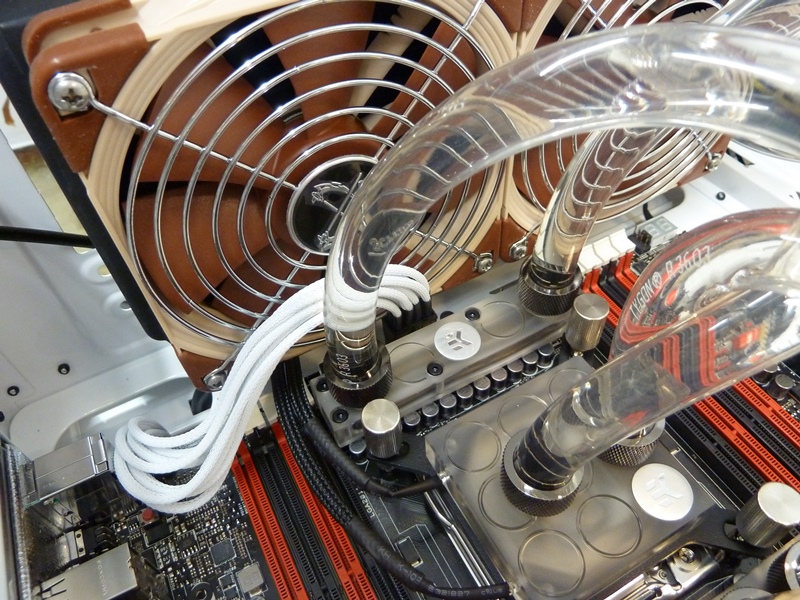

With that said, it's time to move onto building the custom water cooling loop. For this you will need a large hose cutter (10mm-40mm cut radius) and 2m-3m of good quality hose. For my loop I am using clear Tygon R3603 ⅜"ID (Inside Diameter) - ⅝"OD (Outside Diameter) size hose, which was developed for use in laboratories and hospitals originally and allows for very tight bends without kinking.

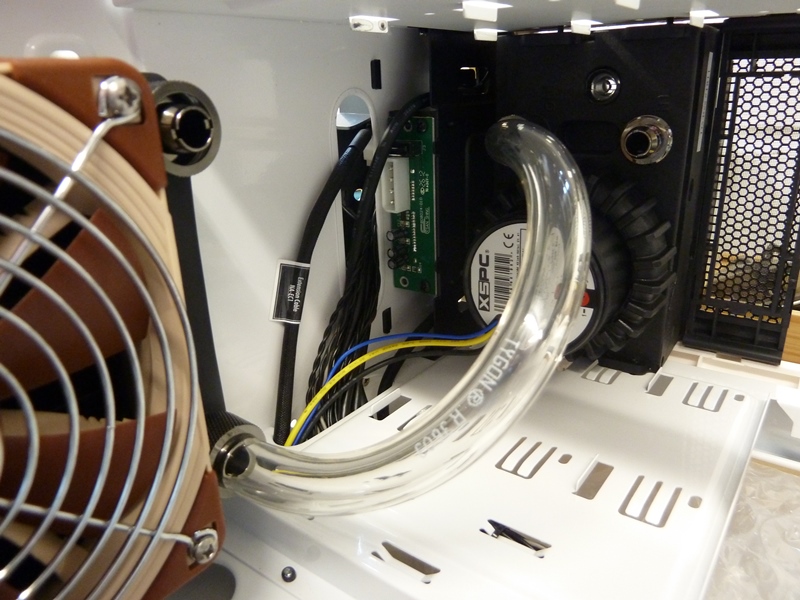

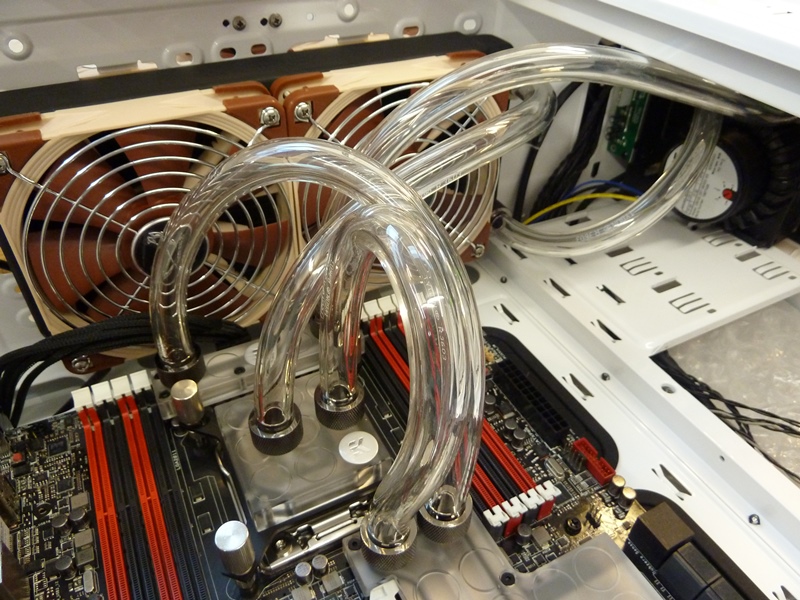

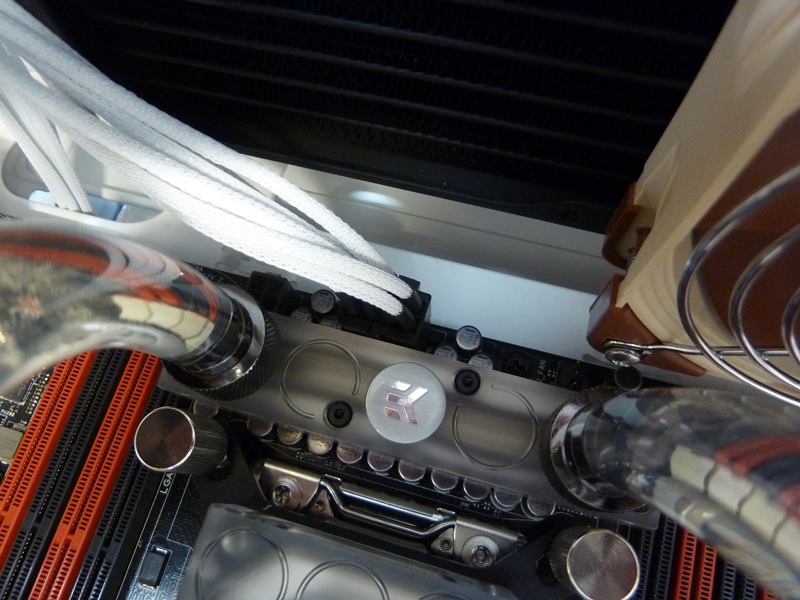

Before you start cutting the hose, work out a plan of how you would like your loop to logically work. The design of my loop is as follows:

START - Reservoir outlet port --> Radiator inside port --> Radiator outside port --> CPU water block left port --> CPU water block right port --> Southbridge water block left port --> Southbridge water block right port --> MOSFET water block left port --> MOSFET water block right port --> Reservoir inlet port - END

When you have decided on your loop design, with the locking fitting removed from the compression fitting take one end of the hose and place it through the locking fitting and firmly push the end of the hose over the barb. Making sure that the hose is fully flush with the fitting. When you are happy, using the locking fitting, compress the hose so that it cannot leak.

Then offer the hose up to the next fitting in the loop and cut the length required. Remember when cutting the hose for the reservoir connections, leave some slack as you will need to pull out the reservoir to fill the system.

Then repeat this process until you have connected all of your fittings together using the hose to complete your water cooling loop.

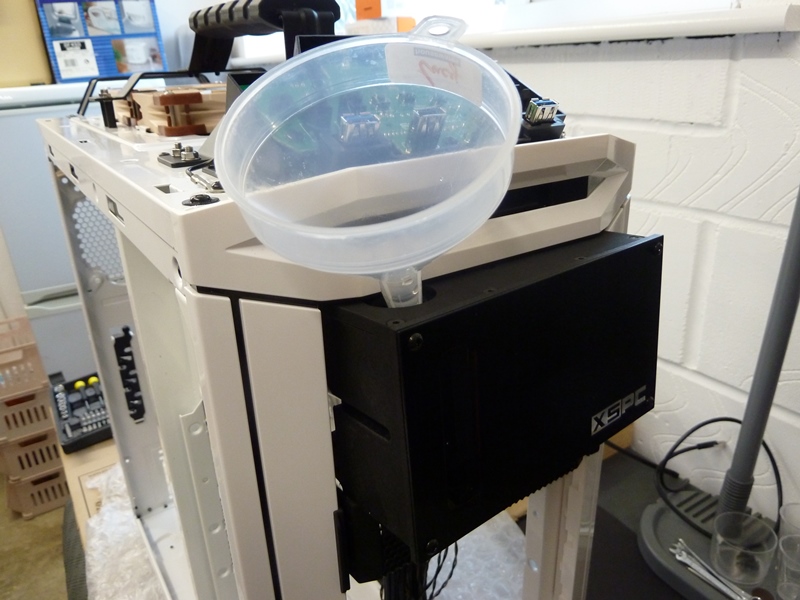

The next stage is to fill your loop. I purchased a small funnel, so that I could easily put the end of it in the fill port of the reservoir. you will need to top up the reservoir several times during the filling and air bleeding process.

With the reservoir filled, you will need to start pumping the water around the loop. For this, I used an old PSU and a 24-pin ATX PSU bridging tool, which can be purchased extremely cheaply. The bridging tool allows the PSU to power peripherals, without the need of a motherboard.

The reason behind why you do it this way, rather than use the PSU in your case and with the power directly connected to the motherboard, is quite simple. Water and electricity don't mix! Performing the fill and air bleeding this way, eliminates any possibility of having a catastrophe should your loop leak!

Next connect you pump to one of the PSU's 4-pin MOLEX connector and the main power to the PSU. Then blip the power on and off in short bursts, then a long single burst until you see the coolant in the hose. You will now need to refill the reservoir and repeat this procedure until both the hose and reservoir are full.

To fully bleed the air from the system, you will need to gently rock your case from side to side, whilst bursting the power on and off to the pump. It may take quite a few attempts. The most important thing to look for is leaks. If you find one, tighten up the compression fitting until the leak desists.

I have to admit here that after I had put my loop together, filled and bled it all that the loop from the CPU water block to the Southbridge water block was actually too long and obstructed the top PCI-E slot, where I need to put one of my graphics cards. To this end, I had to drain down the system and cut two new lengths of hose. Play spot the difference between the photo above and below!

Now, in previous sections, I have gone on about having a logical build order to make sure that every thing fits, well I broke my own rule. I decided that I wanted all of my PSU's cables to be white and individually sleeved. Ergo, I had to remove one of the radiator fans, which was now rather fiddly as the water cooling loop is now in place.

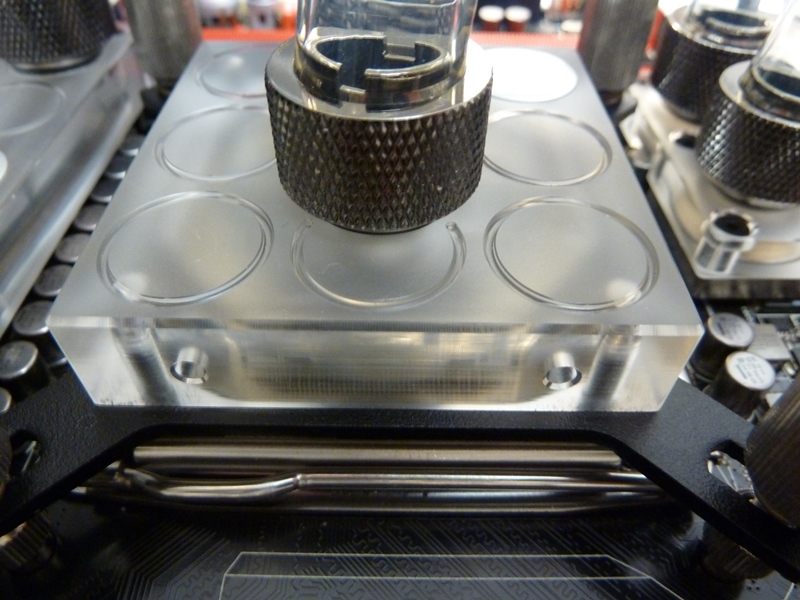

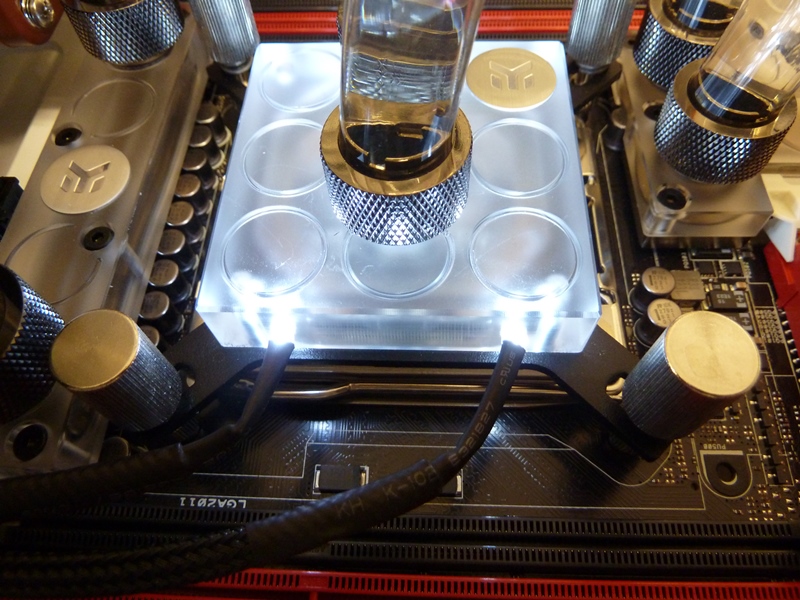

Whilst there is still good access the the CPU water block, I am going to add some 'Bling'. The water block actually has 2 x 3mm purpose made holes in the side of it, to allow you to fit some LED's.

As the LED cables will be visible (and are black - no choice), I have tried to route them as discreetly as possible, across the top of the motherboard. I have pre-calculated that the RAM DIMMs will fit without issue as they will be using the red slots. In fact the RAM DIMMs will help hide some of the cable.

Finally, all that is needed is to test the LEDs - White of course! The connection again is using 4-pin MOLEX, so with your test PSU and bridging tool still in place turn the power on. Overkill or subtle?

Back to Menu Tabs